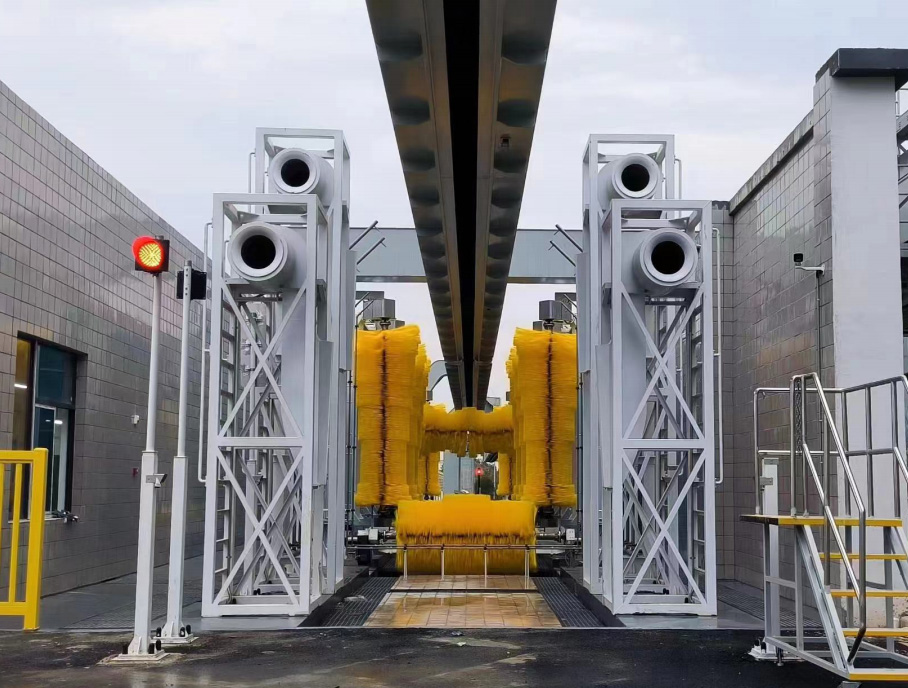

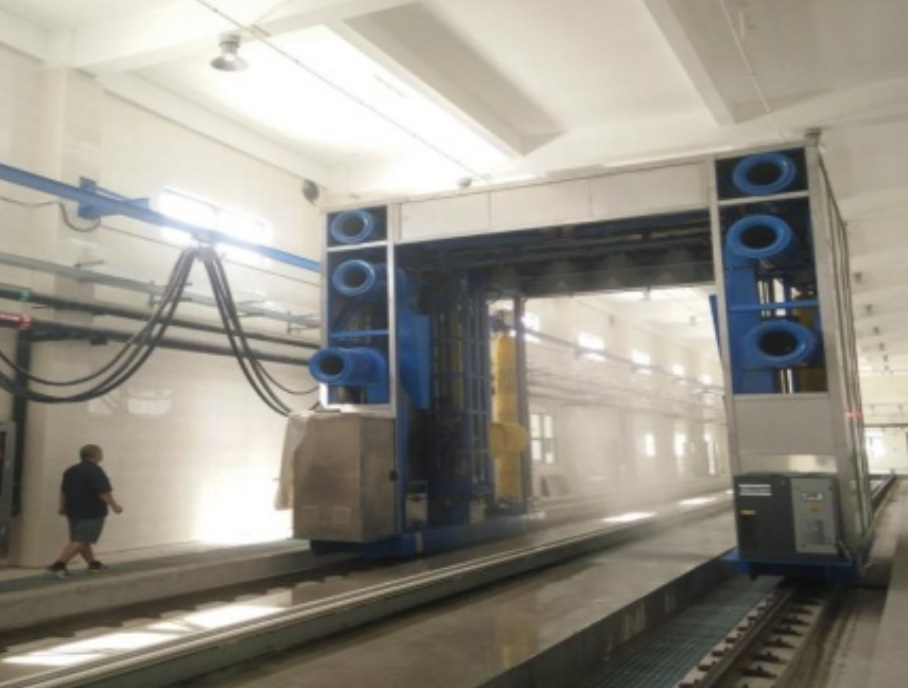

Train washing machines are used for the cleaning operations of the exterior surfaces of variouskindsoftrains (sides, side top arcs, top surfaces, and end faces).Therearemainlytwotypesofsystems:stationary and mobile models. A typical systemis consist of a spray and brush cleaning system, anair drying system, a water supply system, a water recycling and treatmentsystem, and a SCADA data acquisition and video monitoring system.

The system is equipped with high - quality brush,smart cleaning techniques for train ends, reliable windshield wiper protection mechanism, intelligent anti - collision function, and advanced water-treatment technology. It has been successfully applied to various train types such as subways, trams, APM electric multiple units, and monorail vehicles. It can achieve fully automatic unmanned operation and remote control from the DCC (Depot Control Center).

The equipment features easy operation, stable performance, high efficiency and energy - saving, high degree of automation, and convenient maintenance.

| Items | Technical Parameters |

| Power Supply | AC 220V/380V, 50Hz |

| Power | 100kW |

| Train Flow Collection | pantograph/third rail |

| Allowable Train Parking Alignment Precision | ±1m |

| Washing Time | 15 minutes/train (For reference, a six-carriage train) |

| Washing Capacity | 4 trains per hour |

| Train Speed During Washing | 3~5km/h |

| Total Water Consumption | ≤3t/train |

| Clean Water Consumption | ≤800L/train |

| Utilization Rate Of The Circulating Water | ≤3t/train |

| Detergent Consumption | <5L/train |

| Brush Life | 5years(By washing 24 trains ( six-carriage)every day |

| Service Life Of The Equipment | ≥30 years |

Advanced end - profiling cleaning

Advanced end - profiling cleaning Professional imported brush bristles

Professional imported brush bristles Excellent core components

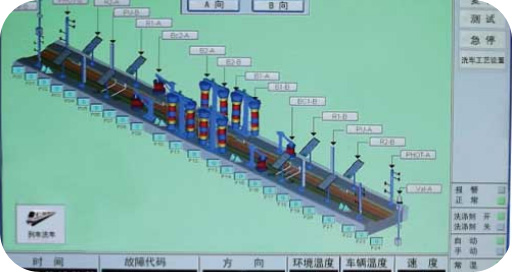

Excellent core components Complete display and monitoring system

Complete display and monitoring system The water cycle system is energy-efficient and environmentally friendly

The water cycle system is energy-efficient and environmentally friendlyTrain washing machines are used for the cleaning operations of the exterior surfaces of variouskindsoftrains (sides, side top arcs, top surfaces, and end faces).

The equipment can perform synchronous lifting operations of a whole or a half of a train set without decoupling, if can also lift one single carriage.

This system enables synchronized lifting of multiple coupled train sets without uncoupling, facilitating inspection,maintenance, repair, and replacement of mechanical, el...

The Electric Road-Rail Shunter is designed for single-unit traction during rail train decoupling and coupling operations.

The electric road-rail shunter (axle type) adopts a battery-powered, four-wheel-drive and four-wheel-steering (4WS+4WD) structure with a high-capacity battery for extende...

The 600-ton Diesel-Powered Road-Rail Vehicle is engineered for shunting railway passenger and freight cars. It provides exceptional traction on rail tracks, ensuring prec...